3.0mm, 4.5mm, or 5.2mm checklist

5.2mm is 44% stronger than 4.5mm mesh

| 3mm | 4.5mm | 5.2mm | |

| will be walked or sat on | |||

| suitable for round river rocks | |||

| straight architectural look required | |||

| building tall, thin structural gabions | |||

| finished wall OK with minor bulges | |||

| lowest cost | |||

| erosion control with high flood velocities | |||

| tall columns or pillars | |||

| furniture seat supports | |||

| requires careful stacking of angular rock | |||

| for use in public spaces |

Angular rock is the best gabion fill as it provides a good interlock and therefore less deformation of the face occurs

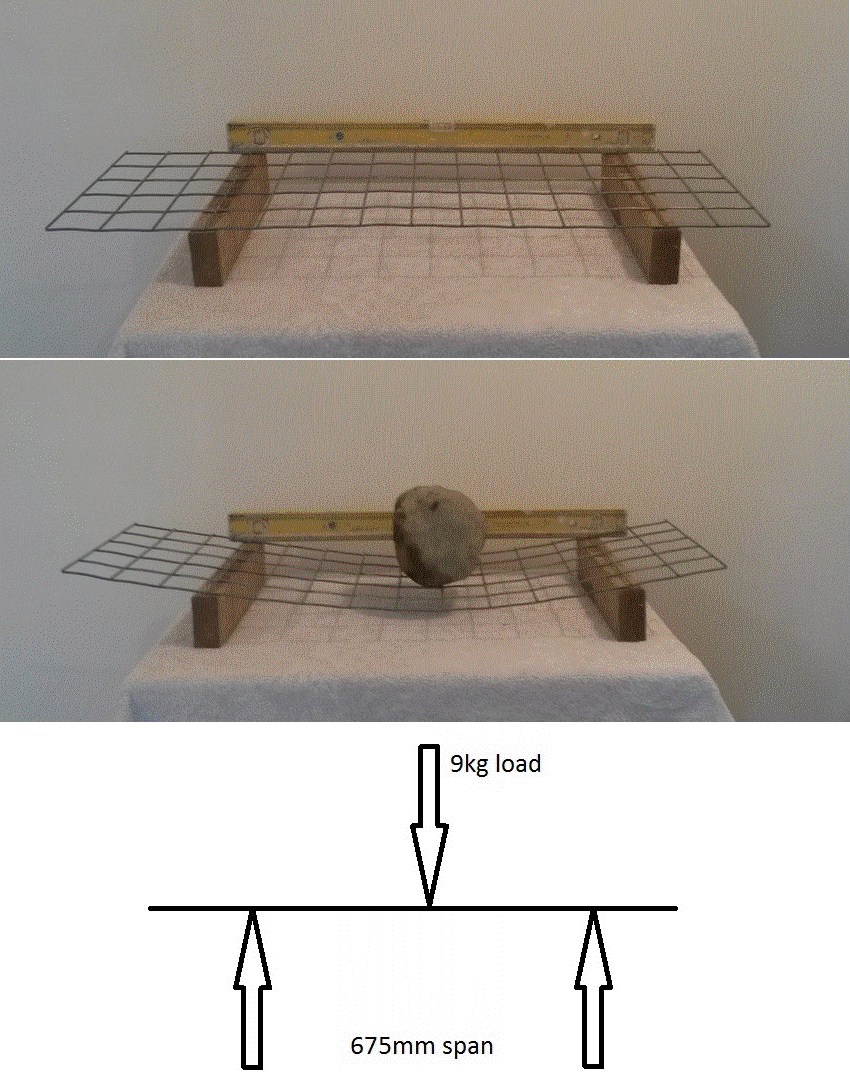

3mm or 4.5mm diameter Galfan coated wire deflection video

Deflection Testing

From time to time, carriers knock or bend the lightweight 3mm gabion mesh in transit.

In most cases this can easily be tapped back into shape.

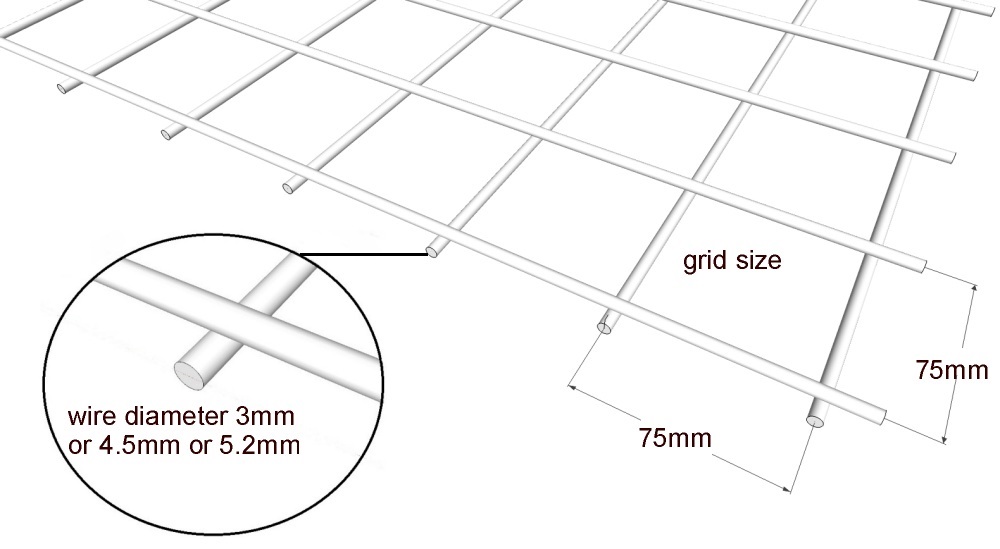

Electronically welded wire mesh 75mm x 75mm grid

Deflection Testing

Gives a good indication of the likelihood of the gabion sides bulging, The size, shape, placement of rock, use of form-work during installation and the number of bracwwires are other factors that can effect the final shape of the gabion.

Deflection Testing

Gives a good indication of the likelihood of the gabion lid bending out of shape, when walked on.

Deflection Testing Results

| Mesh diameter | Deflection |

|---|---|

| 5.2mm | 18mm |

| 4.5mm | 26mm |

| 4.0mm | 49mm |

| 3.0mm | >100mm |

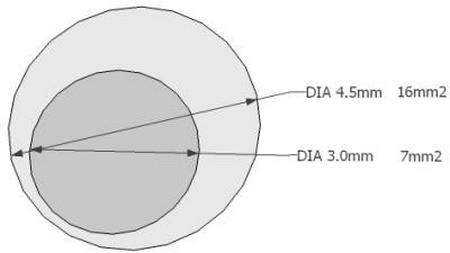

4.5mm dia wire is 125% stronger than 3.0mm dia wire

4.5mm dia wire is 26.5% stronger than 4.0mm dia wire

In locations where high flood water velocities are expected, carrying woody debris and gravels in suspension, the stronger 4.5mm or 5.2mm welded gabions are the preferred choice, to resist damage to the gabion structures during floods.

Click here to add your own text